Repair Service

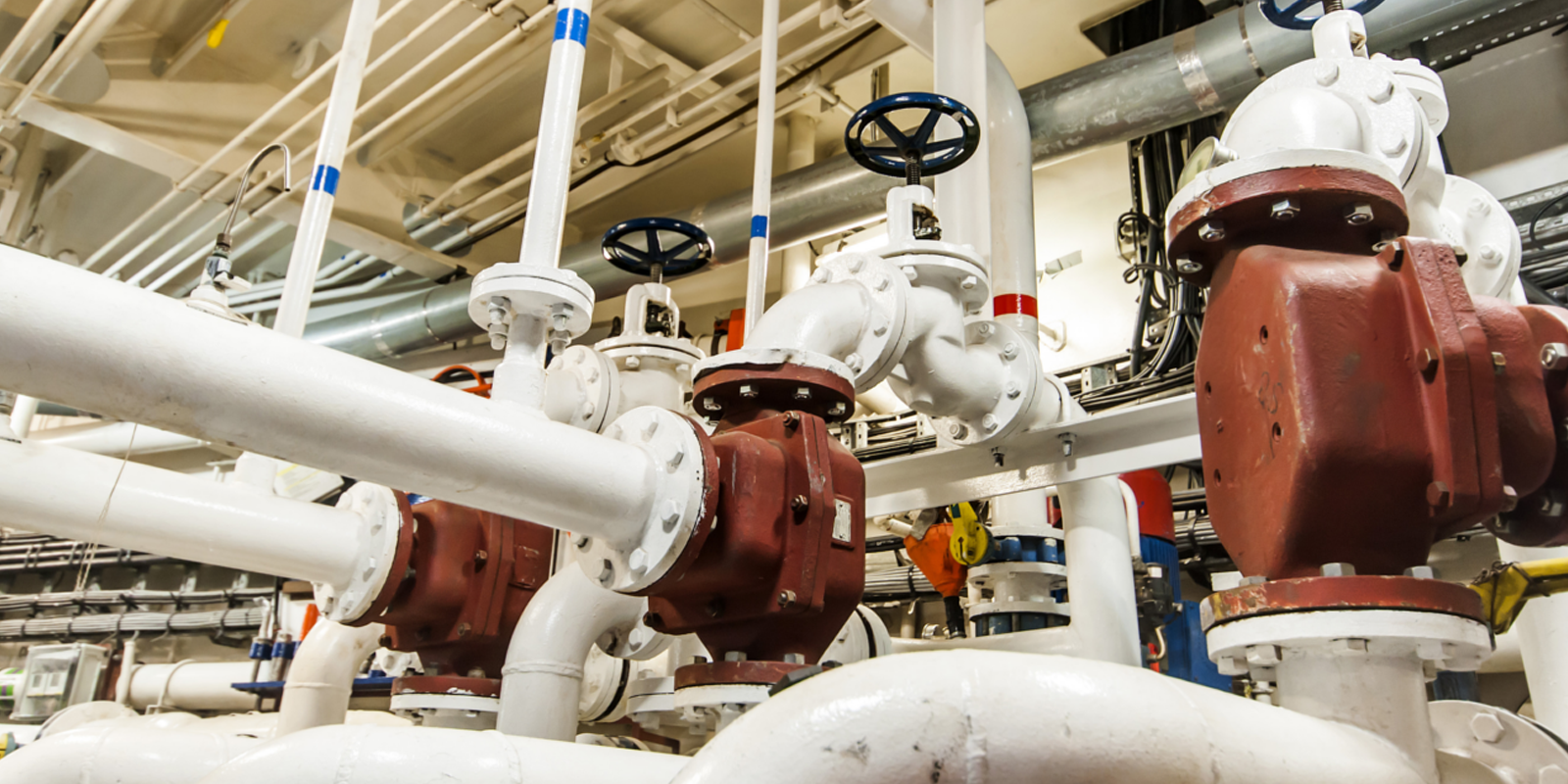

Pipe renewals with zero-leak assurance

Fuel, ballast, cargo, and hydraulic piping is fabricated and installed with precise fit-up.

- CNC pipe cutting and bending

- Prefabricated spool delivery

- Hydrostatic and pneumatic testing

From engineering to pressure testing

Our pipe shop produces labelled spools with weld maps, while onboard teams handle demolition, fit-up, and non-destructive testing.

- Isometric drawings generated for every line

- WPS-qualified welders and inspection teams

- Hydro and pneumatic tests documented with charts

Material traceability

All pipes tagged with heat numbers, certificates, and weld logs for class submission.

Turnkey delivery

Demolition, installation, insulation, and painting carried out by one coordinated team.

Worldwide response

Riding squads repair cracked or leaking lines during cargo operations to avoid off-hire.

Share your pipe renewal scope

Hat listelerinizi ve teslim sürelerini gönderin, imalat planını hemen oluşturalım.

Request pipe plan